How Segmentation-as-a-Service can transform 3D printing at the point of care

Imagine if your printing lab could meet every request for a 3D model quickly and cost-effectively. Imagine if you never had to make that difficult choice between creating a model for one surgical procedure and not another. Imagine if the answer was always yes.

3D print lab managers know the multiple benefits that patient-specific, 3D anatomical modeling delivers to surgeons, patients and healthcare systems. It is becoming a highly valuable, even indispensable tool for gold standard pre-operative planning, especially where the surgery is complex or unusual, and it’s transforming the patient care pathway.

3D modeling delivers:

- Better and faster pre-operative planning, including creating cutting guides and other patient-specific tools for surgeons – an average of 62 minutes saved per case.

- Improved dialog with patients leading to more informed patient consent – 98% of patients agree.

- More efficient procedures and, on average, 16% faster recovery times.

- Greatly reduced risk of discovering something unexpected during surgery.

All of which adds up to better patient outcomes and more cost-effective use of hospital resources. Based on an analysis of current customer trends and feedback, it’s estimated that using 3D models during surgical planning would deliver an immediate and significant financial return on investment for the vast majority of complex surgeries, representing approximately 10% of all surgeries.

So why is 3D printing not yet routinely used in healthcare?

Well, as most 3D print lab managers know only too well, the culprits are time and money or, more accurately, constraints on both. Working within those constraints can leave 3D lab managers feeling understandably frustrated at being unable to provide the level of service they know would provide maximum benefit to their hospital and its patients.

Printing constraints

How many 3D models your lab can produce is limited by printer speed, capacity and affordability. And with different printers required for different types of 3D models, it’s a tall order to equip a lab with every printing option.

However, as technology advances, printers will become more powerful and less expensive, allowing 3D print labs to increase the scope of what they can offer and the level of output. Moreover, if there are periods when demand outstrips capacity, some 3D printing can easily be outsourced.

Budget constraints

There is also the key issue of reimbursement. Currently 3D models are not part of the ‘standard of care’ order so if surgeons request a model, it has to be funded separately. Doing this on a case-by-case basis slows down the lab’s response to requests, with funding not always guaranteed.

But again, this issue will resolve itself with time. Although the broad CPT codes for 3D printed anatomical models and cutting guides are still at trial code stage, it is anticipated that they will move to reimbursement under medical insurance over the next couple of years.

Time and expertise constraints

By far and away the biggest limiting factor to scaling up the use of 3D modeling is the requirement to segment 2D DICOM data sets, such as MRI and CT scans, into 3D printable files. Right now, most 3D print labs have licensed software tools to enable expert users to segment 2D data. But the process is time-consuming, usually taking around 2–5 hours, and requires highly skilled (therefore expensive) staff. And even with the most sophisticated software and the most capable team, scaling the segmentation process will inevitably lead to bottlenecks – not enough staff, not enough hours in the day. Even with a modest demand for 10 or 15 3D print models per day, there are few hospital-based 3D print labs in the world with the available expert staff to even start to tackle this demand,

But for this problem there is an immediate solution.

Scaling segmentation through automation

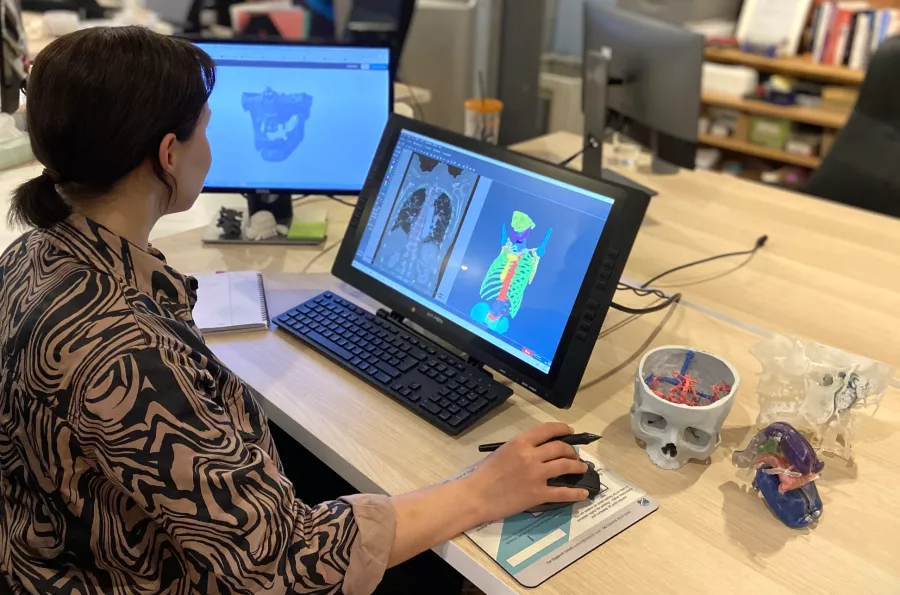

The solution for 3D print lab managers who want to scale up operations without impacting budgets and staffing levels, is automated segmentation. That’s where Axial3D’s Segmentation-as-a-Service™ comes in.

Axial3D has developed machine learning trained algorithms to automatically process 2D DICOM data sets, based on a verified database that contains hundreds of thousands of medical images. In fact, it’s the largest repository of labelled medical images for 3D printing in the world.

With our automated algorithms, the segmentation process takes minutes rather than hours and we can process thousands of cases simultaneously.

Our skilled Medical Visualization Engineers verify the quality of the output, which is typically more accurate than can be produced by even the most experienced segmentation expert. You’ll have the segmented print files in your inbox within hours for you to print and, if required, we can provide you with overflow print capacity - where we also do the 3D printing for you and ship your model to arrive within two days.

The result? Your 3D print lab can scale to meet all of your hospital's demand for 3D models. No more impossible choices, no more bottlenecks, no more ‘No’s’.

The service has already been used by hundreds of hospitals and medtech companies worldwide, and that number is growing month on month.

Next Steps:

We’d welcome the opportunity to tell you more about Axial3D’s Segmentation-as-a-Service™. We know you’ll want to find out how it works, how it would fit with your current 3D printing processes and what it costs. We’ll explain how those costs could be offset by the hospital-wide savings generated by the increased use of 3D modeling.

If you would like to try Segmentation-as-a-service completely free of charge, click the button below!

Discover the benefits of 3D planning with a free model for your next case.

Request a free anatomical model